Fibre Optic Cable Blowing

What is cable blowing? How it works?

With the rapid development of modern science and technology, optical communication technology in all aspects of life have been applied, which makes it received more and more attention. Optical cables, as the carrier of data transmission for optical communication, the proper laying of optical cable is a good guarantee for the dissemination of information data. For a long time, the most common way to lay the cable is to lay the cable directly into the underground, which has been widely promoted and applied.

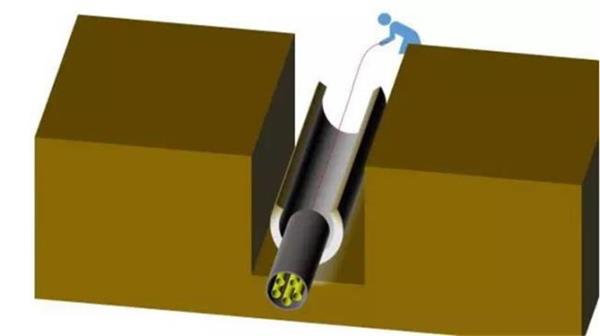

Another way is embedding ducts. Put pipes through the ducts when necessary. Later, the cables should be inserted into the duct by pull, that is, drag them into ducts.

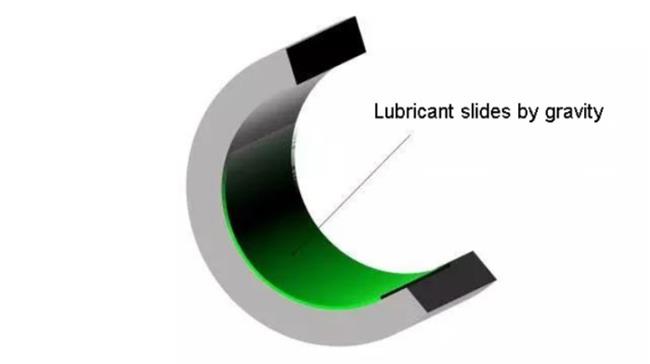

By the fear of force of friction may easy to cause break or deckle-edged of fiber cables, lubricant/oil is pre-applied on the ducts. However, the lubricant will accumulated on the bottom of due to gravity.

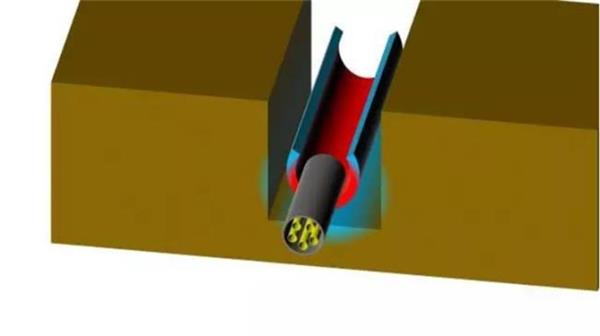

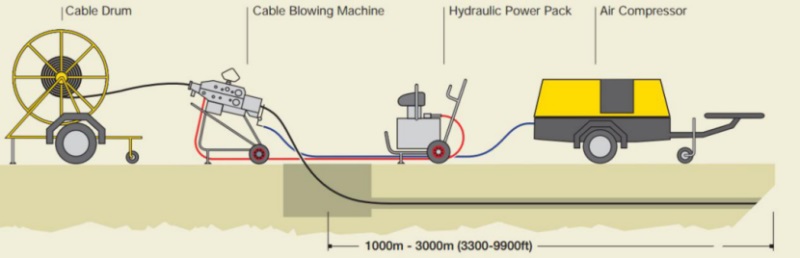

Later, scientists found a new way to laying cable by changing a thinking, laying air-blowing cables. Sometimes called “cable blowing ” , these methods use a high-volume air flow (7 bar back pressure) to “push” the cable. Most blowing machines also have mechanical “pushing”, where the cable is pushed by traction rollers as it enters the duct.

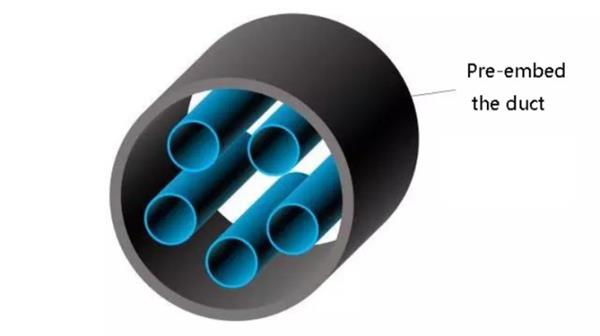

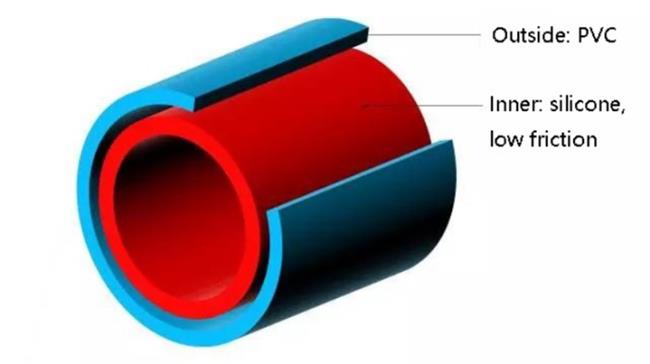

What is the advantages? The outside duct is of PVC, inner pipe is on silicone. Silicone pipe is soft, flexible, but it’s not liquid, won’t slide to be piled. Fibers will be blown in when necessary.

That is cable blowing. It’s more gentle to laying cables compared the ways applied before.

NKF company from Netherlands invented a new execution methods for cable blowing. They use a PVC duct with diameter of 40mm, which allows a number of cables blown in, so project can be staged construction according to business needs and capital situation. Currently, NKF company has successfully applied this new construction method to the cable trunk project from San Diego to Phoenix, the west coast of USA. The project is about 650km totally, the final design of the cable size is 288 cores(5pcs multiply 60 cores fiber cables), divided to 5 constructions. Initially, they only blew one 60 core cable and 5 pipes. In the following days, blow other cables to the rest deserved pipes according to demands. As the plan, the rest construction will be completed in the following 10 years in 4 different times. This will not only meet the current fiber needs, but also save the initial investment costs, warmly welcome by the operating company.

The key features of the cable blowing:

- Protect the cables’ performance better: compared with other cable laying methods, the tension of cable during the laying process is relatively even and much smaller;

- The laying process is simplified, it’s faster and more cost-effective to laying cables;

- The length of one single laying is much longer: you can adopt longer fiber optic cable to reduce the number of joints and diminish the attenuation;

- The number of manholes and hand holes on the pipeline lines can be greatly reduced;

- Labors for laying execution is reduced.

More ……

To read more updated articles about optical communication, please like Facebook page: https://www.facebook.com/sfpcables.